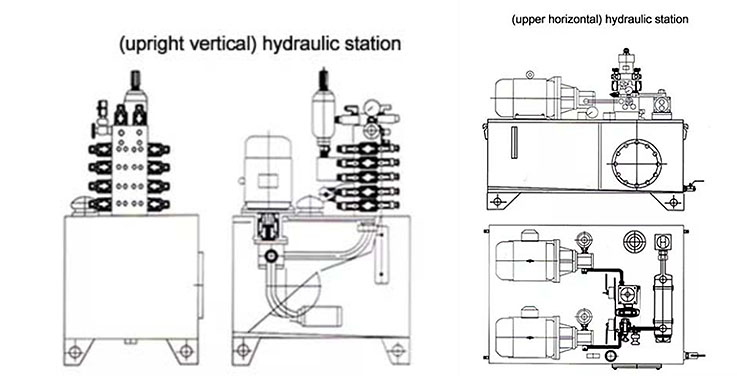

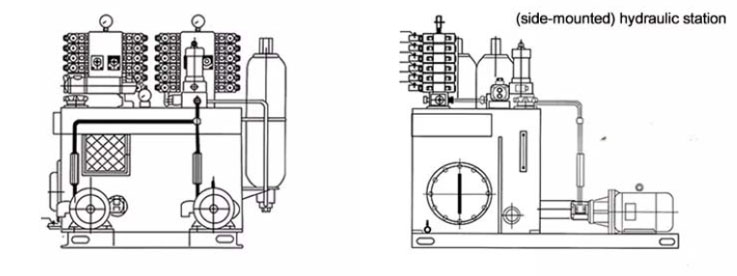

Product detail drawing

Parameter

| Product Name | Custom Hydraulic Power Pack |

| Working Pressure | 6.0 to 30 MPa Depending on requirements |

| Voltage | DC12V/24V AC 220V/380v, Customization is available |

| Tank capacity | Normally 25L~800L. Customization is available |

| Power | 0.75-37.5Kw Depending on requirements |

| Flow | 12-800L/min, Customization is available |

| Size |

Min 400mm*350mm*300mm max 1300mm*1000mm*970mm Depending on requirements Certification |

| IS9001, CE, SGS | |

| Warranty time | 1 Year |

| MOQ | 1 set |

| Lead Time | 15 - 30 days, Pls check with us for expedite or request |

Description

Manifold block - assembled by hydraulic valve and channel body. Direction, pressure and flow regulation of hydraulic oil.

Valve combination - the plate valve is installed on the vertical plate, and the pipe is connected behind the plate, which has the same function as the integrated block. Simple in Operation and control, High level of automation, Easy to change direction, Easy to switch the mechanism rotate movement to the straight line reciprocating movement without changing the motor direction of rotation.

Fuel tank—a plate-welded semi-closed container, which is also equipped with an oil filter, an air filter, etc., for oil storage, oil cooling and filtration. High heat transfer efficiency, Keep the hydraulic Oil at the right temperature.

Electrical box - divided into two types. One is a terminal board with external leads; the other is equipped with a full set of control appliances.

Motor——Copper core motor, Long Life, High efficiency, low vibration, and noise. safe to use. Can be switched from DC 12V to 24V or AC 220Vto 38ov, and the custom input voltage is available.

The working principle of the hydraulic station: the motor drives the oil pump to rotate, the pump absorbs oil from the oil tank to supply oil, and converts the mechanical energy into the pressure energy of the hydraulic station. Connect the pipeline to the oil cylinder or oil motor of the hydraulic machine, so as to control the change of the direction of the hydraulic machine, the magnitude of the force and the speed of the speed, and push various hydraulic machines to do work.

Customizable hydraulic types

According to user requirements andworking conditions, this series of hydraulicstations determine different tank capacity, valve groups, layout and whether specialauxiliary components are provided, suchas coolers, heaters, accumulators, etc.

Picture is for reference purpose only, pls refer to actual product.

Pls contact us for further discussion and details. And pls share withus below information as below.

1. Schematic diagram about your project (ifyou have any).

2. How many actuators(Cylinder/Motor).

3. Working pressure requirement.

4. Hydraulic Cylinders movements/ Hydraulic motor RPM &displacement rate.

5. Speed maintaining & pressure maintaining during operation -Yes/No .if Yes- provide example).

Material: For different products andworking environment requirements, we choose the most suitable metalmaterials.

Machining: Our CNC controlled machinesand skilled operators produce components withtolerance demands down to a few hundredthsof a millimeter, which is a prerequisite for ourown developed hydraulic components.

lnspection: products will be strictlyinspection on our factory QC ProcessSystem.To lnsure the Quality, all of ourproducts process pressure test beforeshipment.

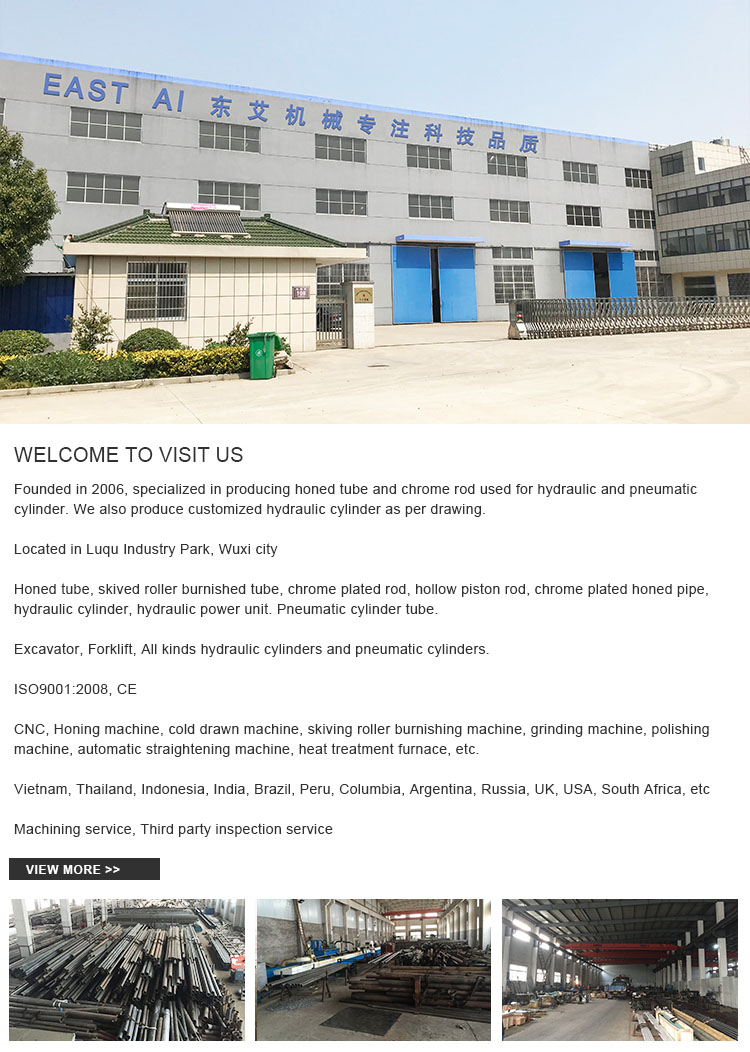

Our company

Mechanical equipment

Certification

Packaging and transportation