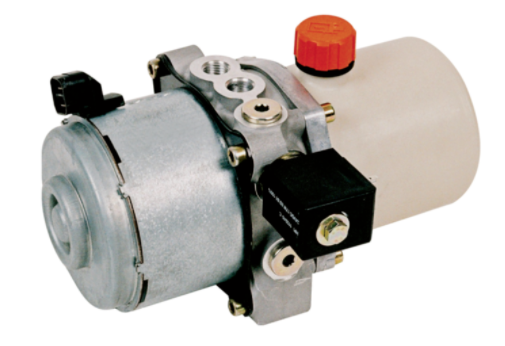

The second generation of HPI hydraulic power unit adopts 100% standardized design concept and contains unique design elements

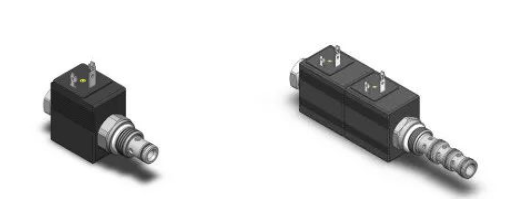

— Die-casting-manufactured central valve block integrates some basic functions of standard cartridge valves

— 1 series gear pump improves the output power and working efficiency for the hydraulic power unit

— DC or AC motors

— By installing cartridge valves in two different groups of oil ports, complex hydraulic oil circuits can be formed, and can be controlled by solenoid valves

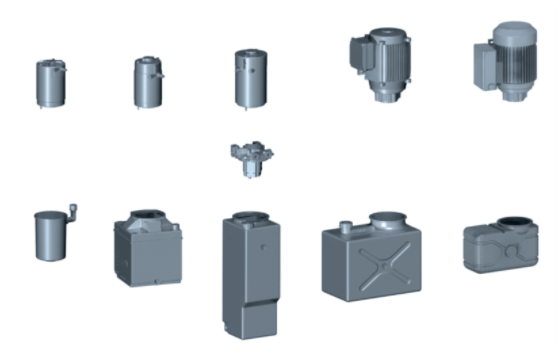

— Fuel tank volume from 0.5 to 25L

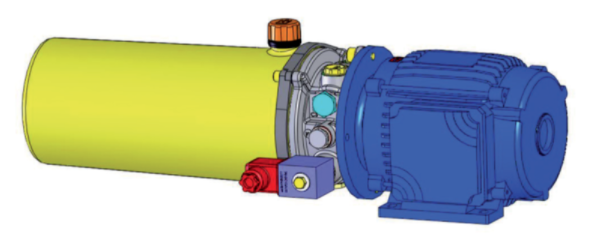

MINI POWER PACK

Product configuration:

— Fuel tank: 0.5~25L

— Flow: 1~25L (DC)

— Working performance: up to 300Bar

— Power: 1.3~4kw, 0.5~4.4kw

The product design of the second generation mini hydraulic power unit can integrate the hydraulic system:

- High power motor.

- Two groups of oil ports on the central valve block can integrate complex hydraulic system functions.

- Use the SMC method to control the integrated solenoid valve on the hydraulic power unit.

- Standardized plastic oil tank makes the product application size smaller.

(*) Soft Motion Control refers to a special solenoid valve control system whose function is to control the voltage increase and decrease of the solenoid valve.

Composition structure:

The design and development of HPI DC motors comes from automotive technology. This technology minimizes the size of DC motors and improves output power and duty.

In order to ensure the maximum reliability and applicability of the product, HPI’s hydraulic power unit adopts the design scheme of directly installing the cartridge valve on the central valve block.

The overflow valve and one-way valve are directly inserted on the central valve block, which also brings convenience for disassembly and maintenance.

On-off valves such as VNF, VNO, VLB, 4/2. 4/3 and even proportional valves can be mounted directly on the central valve block without additional stacked valve blocks.

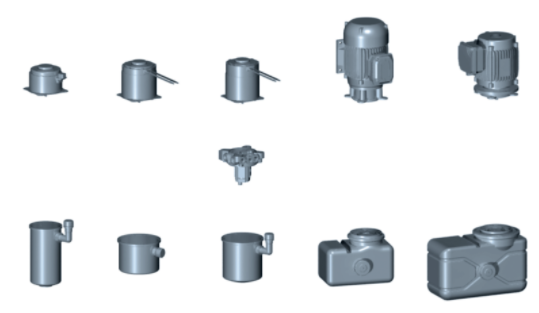

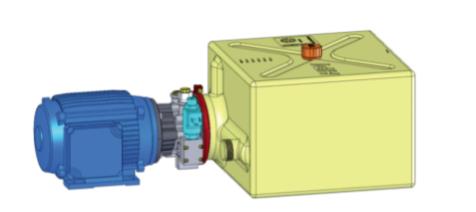

The HPI Micro Hydraulic Power Pack contains:

DC or AC (one-way and three-phase): The motor power is from 0.4~1.2KW, and the structure is very compact. The diameter of the 400W motor is only 100mm, and the length is only 78mm.

- DC:

Flow rate: from 4 to 9 l/min

Maximum pressure: 280 bar

— AC motor:

Flow rate: from 0.4 to 1.2 l/min

Maximum pressure: 280 bar

— Class 0 pump

— Fuel tank: from 0.5 to 6.3 L

MICRO POWER PACK

Product configuration:

— Fuel tank: 0.5~6.3L

— Flow: 0.4~9L (DC)

— Working performance: up to 280Bar

— Power: 0.4~1.2kw, 0.18~1.1kw

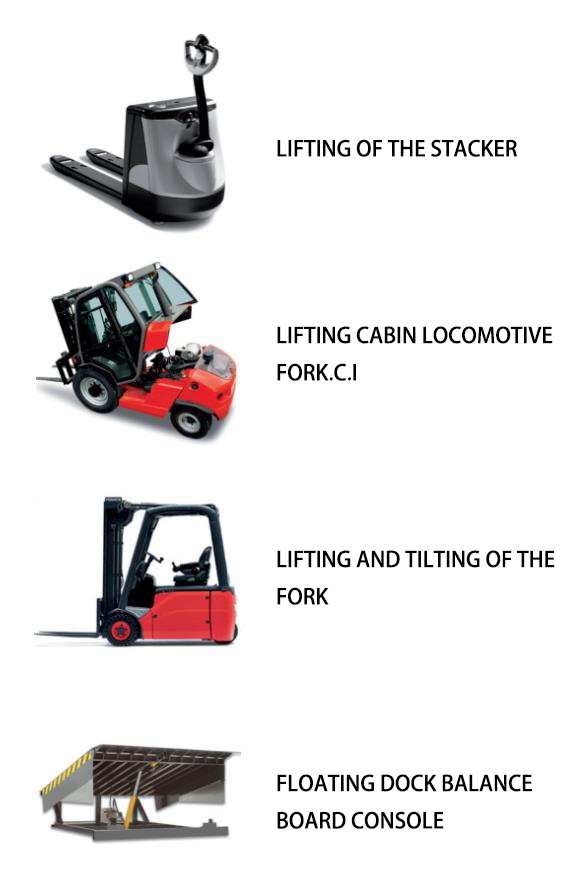

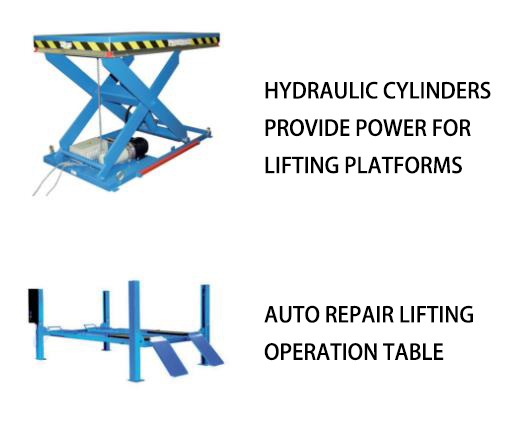

Applicable scene

Tanks for all equipment

High and low pressure performance to meet all power requirements

Working power: DC and AC

Specific tanks designed as required

Complete range of ultra-compact motors for DC and AC applications

Cartridge function concept: enables direct integration of check valves, pressure limiting valves and other valves

Application industry

Post time: Jan-04-2023