Features:

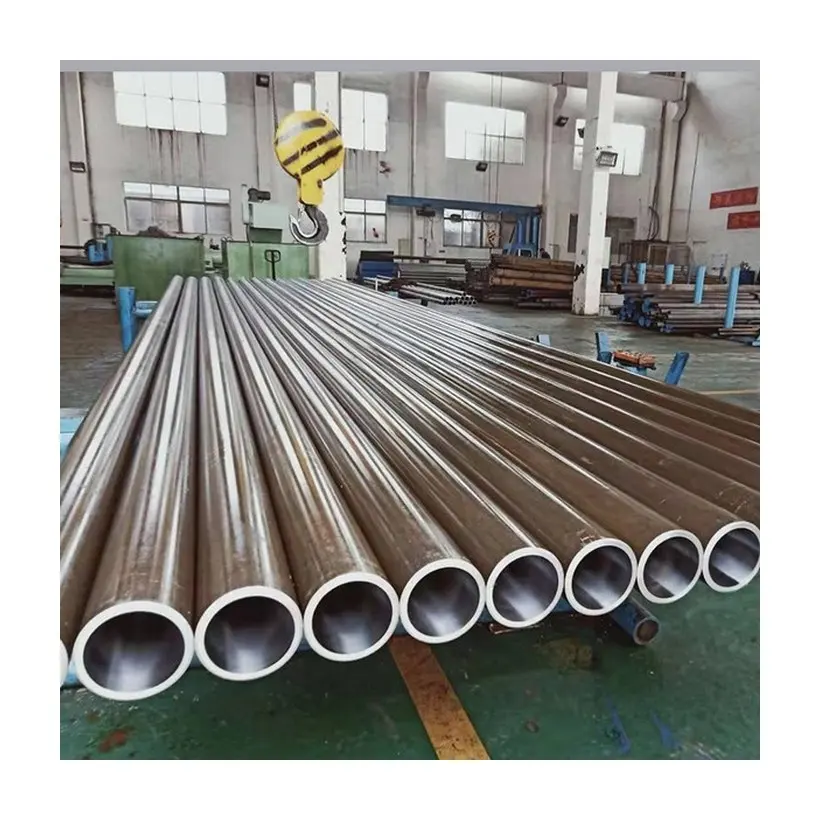

Precision Dimensional Control: The Skived and Roller Burnished Tube is subjected to skiving and roller burnishing processes, resulting in highly accurate inner and outer diameter dimensions that meet stringent engineering requirements.

Surface Quality: Through polishing and roller burnishing, the tube’s surface becomes exceptionally smooth, reducing friction and wear and contributing to improved component lifespan and performance.

Strength and Durability: Skived and Roller Burnished Tubes are typically crafted from high-quality steel materials, offering excellent strength and durability suitable for various high-pressure and high-load applications.

Assembly Performance: Thanks to the tube’s precise dimensions, the Skived and Roller Burnished Tube exhibits better adaptability during assembly, reducing assembly challenges.

Versatile Applications: This type of tubing finds widespread use in industries including hydraulic systems, pneumatic equipment, automotive manufacturing, and engineering machinery, catering to various industrial applications requiring precision tubing.

Advantages:

High Precision: The processing of Skived and Roller Burnished Tubes ensures high consistency in tube inner and outer diameters, achieving precise dimensional accuracy.

Superior Surface Quality: Polishing and roller burnishing create an exceedingly smooth tube surface, reducing friction, leaks, and wear.

Enhanced Efficiency: The high-precision tubing minimizes energy losses within hydraulic systems, thereby enhancing overall system efficiency.

Extended Lifespan: Surface smoothness and precision dimensions contribute to prolonged component life and reduced maintenance requirements.